I own three Thompson Type-Casting Machines.

Two are Lanston Monotype-Thompsons,

acquired in 2010 and 2011 out of Chicago.

The third is a rather old Thompson Type Machine Company machine,

acquired in 2012 in Memphis.

The first two are integral to my shop.

By an odd sequence of events, however,

I haven't actually seen this third machine in person yet.

For technical and historical information on Thompsons in general,

see

../../ Noncomposing Type Casters -->

Noncomposing Type Casting Machines ->

The Thompson Type Caster.

TO DO:

Parts to examine and measure on other machines for comparison:

- a77TC12 Pump Stop Plate Screw Collar

(and b77TC2 Pump Stop Plate Screw, while I'm at it)

- a84TC9 Stop Motion Crank Disk Screw (to shaft)

- a84TC7 Stop Motion Crank Disk dowel (to shaft)

- a84TC12T (a84TC12 & a84TC13 assembled)

Stop Motion Hand Wheel Stud Spring

- a84TC14

Stop Motion Hand Wheel Stud Spring Screws (2)

- 37TC10 Splash Guard

This is a historic machine.

It was the last typecaster from the last

commercial typefoundry in Chicago.

Others continue to cast noncommercially in Chicago,

but when I hauled this machine home in December of 2011,

it brought to a close a century and a half of commercial

typefounding in Chicago.

This is an "American" Thompson typecaster

manufactured by the Lanston Monotype Machine Company of Philadelphia.

Serial No. 13,068.

This was my second Thompson.

I acquired it from the former Barco / F&S Type Foundry in

Bensenville, IL.

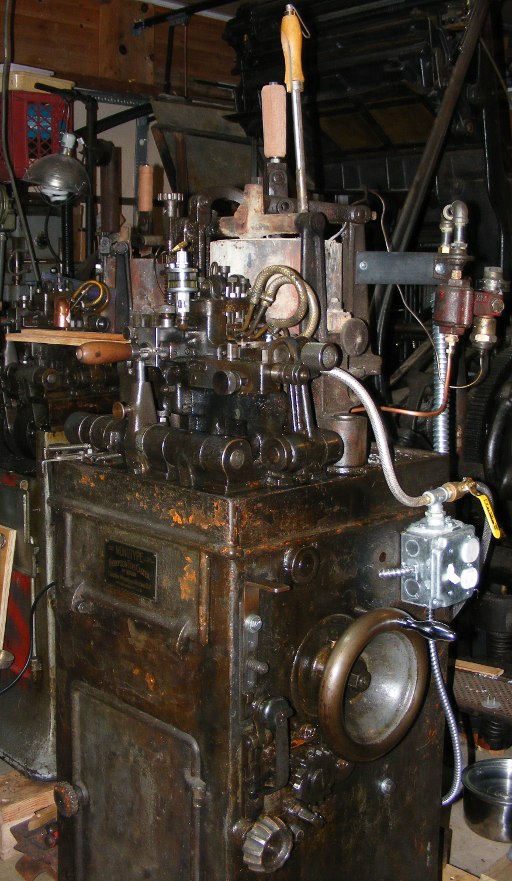

It may still look a bit rough in the photo below,

but this actually represents a rather large amount of work.

I've stripped off a huge type receiving galley and made a proper

type receiving stick,

installed a sight-feed oiler (and oil hole covers; not visible here),

put a handle on the piston, put a thermometer in its well

(had to drill out the well for that),

moved the Partlow controller a respectful distance from the pot,

re-plumbed all of the gas

(using copper tube, not rubber, to the burner!)

and re-orificed the burner for propane,

re-plumbed the water,

re-wired the motor for 120V,

re-done the electric supply wiring

(adding a fused disconnect, not visible here),

and fitted a nice revolving handwheel handle

(carefully saving the original Thompson part).

There's a lot of other work not visible in the photo,

including cleaning out all of the oil passages

(many plugged with typemetal),

re-adjusting every single adjustment on the mold stand,

and re-mounting the motor

(the motor mount had been installed upside-down).

As shown, the machine has just been casting

(the observant will note that the piston pin has been removed,

but in this case I've left the piston in the machine).

[click image to view larger]

Status:

Acquired December, 2011.

2011-2012.

Work to revive the machine,

including the clearing of all oil passages.

(They were

all blocked, many with typemetal.)

Installed oil hole covers.

Rewired motor to 120V.

Drilled out (carefully!) pot thermometer well and put a thermometer in.

Constructed wiring controls and water controls.

Built Type Stick.

Attempted to run with original Thompson burner,

converted to propane.

Failed to achieve operation at safe CO levels,

so discared it and installed a modern burner.

Limited test-casting of type with

0.050" mold (successful),

Ludlow mold (successful, but excessive flash),

and

Linotype mold (not successful; squirt due to VMB interference).

See

Thompson Molds, below.

2014, June.

Moved this machine into the in-process Type Foundry,

and with the help of Sky Shipley successfully cast type with it

using an 0.050" mold and Lanston display matrices.

The service setup (gas, water, electricity) in this operation

was temporary.

2014, December.

Examined machine more thoroughly as a part of the project to

do a teardown of 13,068 (as I would be temporarily swapping parts

from this machine to '068 so as to show a teardown of a

nearly completely equipped machine).

Status as of this evaluation:

The machine is in casting condition,

but the Stop Motion is not functional

and the Pump Stop is not fully reliable.

Details:

- Pump Stop:

- a77TC12 Pump Stop Plate Screw Collar as aquired

doesn't seem quite right.

The b77TC2 Pump Stop Plate Screw also, as acquired,

seems to require a washer never specified in the Parts List

or shown in the manual.

Further study is required.

- Stop Motion (NOT fully functional):

- Tapped Hole in

a18TC5T Friction Wheel Shaft appears to be 1/4-24 U.S.S.;

this appears to be original.

But the item acquired with the machine which functioned as

a84TC9, the screw for attaching a84TC6 Stop Motion Crank Disk to it,

is a munged, bent, wrong replacement.

Discard it. Must acquire/make new a84TC9.

- The item acquired with the machine which functioned as

a84TC8 Stop Motion Crank Disk Pin, is undersized.

Discard and fabricate a proper a84TC8 pin.

- The item acquired with the machine which functioned as

a84TC12T Stop Motion Hand Wheel Stud Spring

(assembled) is a 1-part replacement for the 2-part original.

But it works, so keep using it.

- Mold Stand:

- 54TC8 Mold Stand Cap Adjusting Eccentric (Mold Jet Block)

is screwed on so firmly that it cannot easily be removed.

At present this is not an issue.

- The part functioning as

a54TC13 Mold Stand Cap Adjusting Screw (Mold Top Block)

(Large Head) (Long)

is as acquired an

a54TC12 (ditto, but Small Head).

This works, but at some point I should acquire or

fabricate a proper a54TC13.

- Cam Rollers:

- The item acquired with the machine which functioned as

53TC7 Vertical-Mold-Blade-Cam Lever Roller Stud

has no screw slot in it and must certainly be a non-Monotype

replacement.

It is nearly impossible to remove.

It works for now, but should be replaced with a proper

53TC7 (original or newly made).

- The item acquired with the machine which functioned as

30TC9 Matrix-Carrier-Cam Lever Roller Stud

has no screw slot in it and must certainly be a non-Monotype

replacement.

It is nearly impossible to remove.

It works for now, but should be replaced with a proper

30TC9 (original or newly made).

- Type Stick is my replacement. It isn't quite right, so make a new one.

- Piston Lever

- As acquired, hole in 69TC1 Piston Lever for

a69TC4 Piston Lever Pin Set Screw is oversize.

The random screw supplied in place of a69TC4 simply slides

through it and the hole in 69TC3 Piston Lever Pin.

This is crude, but it works and probably does not need

to be changed.

- To Do: Fabricate and install a lock-out for high-speed operation.

- Water control.

Re-do so that it is not on top of the electrical box.

As-is it is very thoroughly sealed, but it just doesn't

look/feel right.

- 37TC10 Splash Guard not fitted (I don't have any).

This part is not needed,

but it might be nice to fabricate a replacement someday,

if only for show.

- Oil Hole Covers:

None acquired with machine.

Presently using Gits Mfg. Co. p/n 00205 Style O Threaded Oil Hole Covers,

threaded 3/8-24 UNF.

- Sight-Feed Oiler:

None acquired with machine.

Presently using an Essex OC33A0/00 oiler, 1 1/4" dia.

This works fine, but is very slightly oversized.

Attempt replacement with smaller ex-Monotype Composition Caster

brass oiler

acquired from Firefly Letterpresss.

- Hand Wheel:

I have removed the 10TC14 Clutch Shaft Hand Wheel Handle

(and carefully preserved it)

and replaced with a modern revolving hand wheel

(Enco, "Gibraltar" house brand, stock no. 319-7678, 3/8-16 thread,

3 3/8" length overall;

identical to MSC stock no. 7741-4431 but cheaper).

An "American" Thompson typecaster

manufactured by the Lanston Monotype Machine Company of Philadelphia.

Serial No. 13,068.

This was my first Thompson.

I acquired it from the former Barco / F&S Type Foundry in

Bensenville, IL.

Acquired November 2010.

This is the machine used in

A Complete Teardown

of a Thompson.

This is a picture of it in my shop in late 2010,

but before I'd had a chance to do any work on it.

Although it was in commercial operation when acquired,

it still needed extensive work.

(Rewire for 120V, re-orifice and re-plumb for propane,

move gas regulator to a safe distance from the pot,

new sight-feed oiler (old one missing),

new oil hole covers (old ones missing),

clean oil holes plugged with grease,

clean oil holes plugged with typemetal, etc.)

I cast my first type on it in April 2011,

but I cast only a few pieces and then shut it down pending further maintenance

(fix retaining pin in Matrix Carrier Fork,

new Matrix Carrier Lever Cam Follower (old one faceted),

new Pump Lever Cam Follower (old one worn too small),

install cooling system,

get missing parts for Stop Motion,

probably remove the monstrous type receiving fabrication,

make proper type receiving stick,

and still more cleaning).

[click image to view larger]

Status:

Acquired 2010-11-21.

2014, December.

Examined machine more thoroughly as a part of the project to

do a complete teardown of it.

Status as of this evaluation:

The machine is

NOT in casting condition.

The critical issue is the Pump Stop,

which is not functional at all

(but the real problem may be wear to the

a76TC1T Pump Cam Lever and/or the

2TC13 Pump Cam Block).

The Stop Motion is missing important pieces.

There are various less important issues as well.

Details:

- Type Stick:

- 81TC1 Type Stick missing. Fabricate a replacement.

Get it right this time.

- a81TC4 Type Stick Screw (to Mold Stand).

Only have one (second as acquired was a munged wrong replacement).

Find or fabricate a proper second a84TC4.

Or at least get a nice looking screw.

- 45TC3 Type-Body-Piece Plate Connecting Pin Clamp Screw.

Missing. Acquire or fabricate.

- Pump-Cam Lever:

- a76TC9 Roller Stud Screw was not present on the machine

as acquired.

(There isn't much clearance, so the Roller will stay on

without it.)

Acquire or fabricate a replacement.

- Gas Burner:

- I fitted the original Xa20TC Gas Burner group which was

acquired with this machine for purposes of the teardown.

I plumbed it to the Partlow with copper, as I did when I

tried originally to use it.

However, this burner cannot be used safely with this machine

and it will be returned to stores after the teardown

and replaced with a modern burner capable of operating at

safe (zero) CO levels.

- Stop Motion Ratchet Wheel (all of these missing; acquire or fabricate):

- 84TC25 Stop Motion Ratchet Wheel

- 84TC27 Stop Motion Ratchet Wheel Pin

- 84TC26 Stop Motion Ratchet Wheel Screw (stud)

- 84TC28 Stop Motion Ratchet Wheel Friction Washer

- Stop Motion Crank Disk (all of these missing; acquire or fabricate):

- NOTE: Threaded hole in a18TC5T Friction Wheel Shaft

into which 84TC9 Stop Motion Crank Disk Screw screws

to attach the Crank Disk

was probably originally

1/4-24 U.S.S, approx. 1" deep

(as it still is on machine 12,492).

But on machine 13,068 it has been partly drilled and

tapped oversize to 5/16-18 for 0.29".

This is

larger than the hole in the

Crank Disk.

- 84TC6 Stop Motion Crank Disk [see note above for oversize hole requirements]

- 84TC8 Stop Motion Crank Disk Crank Pin

- 84TC7 Stop Motion Crank Disk Dowel

- a84TC9 Stop Motion Crank Disk Screw

- Hand Wheel:

- 10TC17 Clutch Shaft Hand Wheel Stud (for Stop Motion)

is missing. Acquire or fabricate a replacement.

- No 10TC14 Clutch Shaft Hand Wheel Handle was present

as acquired.

I have installed a modern revolving hand wheel

(Enco, "Gibraltar" house brand, stock no. 319-7678, 3/8-16 thread,

3 3/8" length overall;

identical to MSC stock no. 7741-4431 but cheaper).

- Mold Stand:

- The part functioning as

a54TC13 Mold Stand Cap Adjusting Screw (Mold Top Block)

(Large Head) (Long)

is as acquired an

a54TC12 (ditto, but Small Head).

This works, but at some point I should acquire or

fabricate a proper a54TC13.

- The tapped hole in the Mold Stand for the left front

54TC18 Mold Stand Cap Screw must have been damaged in the past,

as it has been drilled out and tapped oversize (as acquired).

An oversize screw has been installed, the head of which

bears on the top of the Mold Stand Cap (i.e., it is not

countersunk). Ugly but effective; leave as is.

- 37TC10 Splash Guard not fitted (I don't have any).

This part is not needed,

but it might be nice to fabricate a replacement someday,

if only for show.

- Oil Hole Covers:

None acquired with machine.

Presently using Gits Mfg. Co. p/n 00205 Style O Threaded Oil Hole Covers,

threaded 3/8-24 UNF.

- Sight-Feed Oiler:

None acquired with machine.

Presently using an LDI p/n RDF101-11,

"Reservoir, Drop Feed Pipe Thread NPTF (Dryseal)"

Thread 1/8 NPTF, capacity 5/8 oz.

McMaster-Carr p/n 1167K51.

This works fine, but is noticeably oversized

and isn't brass.

Attempt replacement with smaller ex-Monotype Composition Caster

brass oiler

acquired from Firefly Letterpresss.

The following parts were borrowed from

12,492 for use in illustrating

A Complete Teardown

of this machine.

I'll list them here for my own reference,

just so I don't look at the photographs of that teardown years from

now and wonder "where did that part go to?"

when it wasn't really a part from this machine.

- 81TC1 Type Stick

(my replacement, NOT the real Xa81TC Type Stick group)

- 45TC3 Type-Body-Piece Plate Connecting Pin Clamp Screw.

- Pump-Cam Lever assembly

(a76TC1 Lever,

w/ a76TC5 Roller, a76TC6 Roller Stud, and a76TC9 Roller Stud Screw).

Machine 13,068 is missing only the a76TC9 screw,

but it's easiest to swap levers for the teardown).

- Mold Stand Cap:

Entire assembly borrowed from 12,492, along with

a42TC40 Mold Jet Block Lifting Stud Yoke and

a42TC51 Mold Top Block Lifting Stud Yoke (with screws for both).

- Stop Motion Ratchet Wheel:

- 84TC25T Stop Motion Ratchet Wheel, assembled w/ 85TC27 Pin

- 84TC26 Stop Motion Ratchet Wheel Screw (stud)

- 84TC28 Stop Motion Ratchet Wheel Friction Washer

- Stop Motion Crank Disk [See machine 12,492 notes for problems with these]:

- 84TC6 Stop Motion Crank Disk

- 84TC8 Stop Motion Crank Disk Crank Pin

- 84TC7 Stop Motion Crank Disk Dowel [undersized; wrong part]

- Find a screw to use as a stand-in for a84TC9 for photography;

the one from 12,492 is very bad, and wrong,

and I haven't yet made a correct replacement.

- Entire Hand Wheel assembly

(10TC13T Clutch Shaft Hand Wheel, incl. Handle, Key, Nut, and Stud).

13,068 has everything except the Stud,

but it's easiest to swap the entire Wheel assembly vs. removing the Stud.

- Xa13TC Side Door borrowed entirely (it's nicer looking than the

one on 13,068, which has an ugly chain-drilled cutout).

The following parts were taken from spares and fitted for show

during the teardown;

I don't generally keep them on the machine:

The following parts were not shown on the teardown because I

don't have them at all: