A record of the events in acquiring a rather large Barth type casting machine and bringing it back into service. This is an informal diary; for the presentation of the results of this project, go up one level to the main Barth Notebook .

This is also a convenient place for me to keep a brief and incomplete To-Do List:

Barth To-Do, (only slightly!) Deferred:

2018-07-26: Cycling under Power

On July 26, 2018, the 60 point Barth cycled under power (pot cold) for the first time since at least 1993. There are some issues which will need attention, because it is now clear that in 1993 ATF was running the machine into the ground.

2018-07-25: On Flat Belting

Notes on making up flat leather drive belts. Later I need to expand this into its own Notebook separately from the Barth.

2018-07-13: Reeves Speed Control

The Reeves "Motor Pulley" (that's the model name) variable-speed drive from the motor to the rear of the machine. Running it, and an issue with it.

2018, June (B): Measuring a Mat ('M')

[WRITEUP NOT DONE, although the handwritten notes are online in the "Data and Tables" Notebook]

2018, June (A): Measuring the Shoe and Slipper

[WRITEUP NOT DONE; the work itself was done back in 2016] A Barth Type Caster has two removable pieces which hold the matrix: a "Shoe" with two pins which engage with holes drilled in the mat, and a "Slipper," which is a kind of a shim which fits between the Shoe and the mat. Two No. 3 1/2 Barths survive, but only one Shoe and one Slipper. I borrowed these from Greg Walters (they're now in use on his 72 point Barth) and measured them. There is now a CAD model of the shoe. Work to do: CAD model of the Slipper. Proper engineering drawings of both Shoe and Slipper. Make new ones for the 60 point machine.

2018, May (D): Motor Wiring

[WRITEUP NOT DONE] Wiring from the new phase converter to the existing Barth motor. Issues of restorative conservation. Discoveries of ATF industrial sabotage. Learning about machine wiring (vs. building wiring). Matters of wiring safety and code.

The setup I created is safe, and works. It is not quite what I would build now if I was to do this again from scratch. All of these Notebooks and Barth Journal entries document what I did (as best I could); they do not pretend to instruct you in what you should do. This is especially true with things having to do with electrical wiring. Three-phase 240V can kill you instantly, and I am not qualified to teach you how to work with it.

But on May 26, 2018, the motor on the 60 point Barth ran under power for the first time in at least 25 years.

2018, May (C): Phase Converter

[WRITEUP NOT DONE] Wiring up an American Rotary model ADX-5 single-phase to three-phase rotary phase converter. It's a very nice unit.

2018, May (B): Power Issues and Options

This entry describes in general terms (not installation-level details) the decisions I came to for handling the electrical power to the Barth. It also reviews briefly the history of the motive and heating power for the machine; without knowing this history, nothing makes sense.

2018, May (A): Restart and Reorientation

After another two-year delay, I am finally able to return to this machine. But the project has changed in the interim. The last thing that I realized when I worked on this machine two years ago was that if I were to continue as I was, I would begin to destroy the very history that I wished to preserve. So to move forward now I need to apply the principles of "restorative conservation" so as to bring this machine back to life without killing it.

2016-07-18: Parts List Started - and Electrics

It's the middle of July already, and I am indeed falling behind on work on the Barth (though a press and other equipment were saved in the interim). It's not quite as bad as it looks, though, as I'm falling further behind on Jounal entries than actual work. At present, I've now been through the entire electrical system and almost understand it.

I've also begun one of the basic documents for the machine: a Parts List. This Journal entry, then, is a snapshot as of today of this Parts List. It is complete for one Group of parts, 91BCD - the electrical system, except for one (important) item: a schematic. I'm still working converting phsyical wiring drawings into a schematic diagram. Click on the icon above to see this current snapshot of the Parts List. For more up-to-date versions in the future, see the Barth Notebook on Parts Lists.

2016-05-31 / 2018-05-27: Safely Cycling the Machine

[Restarted and finished two years later, on 2018-05-27] In most typecasting machines there are situations where if you cycle the machine, by hand or under power, you'll break parts. It's true of pivotal type casters, it's true of the Thompson Type-Caster, and it's true of the Barth. When can you, and when can you not, cycle the machine without damaging it?

(This addresses the safety of the machine, not that of the human operator. That's a different matter altogether.)

2016-05-31: Observations

Flywheel and Camshaft relative rates of rotation. Always operating on two types at once. Two Choker Valve openings, and the successive Pump drops. The why of cute little big machines.

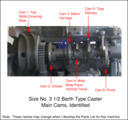

2016-05-31: The Main Cams Identified

They simultaneously drive and control/time all of the various mechanisms of the casting machine. They're the best place to start understanding it.

2016-05-31: Direction of Flywheel Rotation

It's not hard to figure out, but you've got to know.

2016-05-28: The Underside of the Base

Something you don't see everyday. It reinforces (pun intended) the idea that the Barth is massively constructed. But it also shows some questionable design decisions which caused issues which were overcome by brute force rather than bypassed by elegant design.

This Barth Journal entry is in its subject pretty minor - a part of the machine you'll never ordinarily see. But it leads out into several other issues: presentation of original data, CAD models and drawings, and a parts symboling scheme.

2016-05-21 to -28: Unpalletizing

4,000 pounds four inches off the ground is too high up.

All portions of this document not noted otherwise are Copyright © 2014, 2016, 2018, 2022 by David M. MacMillan.

Circuitous Root is a Registered Trademark of David M. MacMillan.

This work is licensed under the Creative Commons "Attribution - ShareAlike" license, version 4.0 International. See http://creativecommons.org/licenses/by-sa/4.0/ for its terms.

Presented originally by Circuitous Root®