The current (at least as of 2012) Famco catalog (available online) notes that various versions of the Model 375 used grinding wheels of different hole sizes. I've only got a Model 375-4, so everything here will pertain to that. (If you look at the wheels offered for the 375-3, they're all 7/16 inch hole size while the 375-4 has a 7/8 inch hole.)

According to the current (as of writing, in 2012) Famco Model 375 Universal Cutter Service Manual, on page 8, the maximum rotational speed of the Famco/Lars/Gorton 375-4 is 4,740 RPM. (In factory-equipped machines, there are supposed to be two speed ranges, a low speed of 1,440 RPM and a high speed of 3230 RPM; my machine was clearly not equipped with a original factory motor as I received it.)

Note that this maximum speed exceeds that of many grinding wheels. Further, it is easy to remotor or re-belt a machine so as to exceed its maximum. Care must be taken, therefore:

If run too hard, a grinding wheel's surface may glaze over and render the wheel unfit for use until restored. The same thing happens to a human brain after reading just a few too many part numbers...

Famco (or Lars or Gorton) do not (at least anywhere I can find) specify the wheel types to be used with this machine. The closest they come is to describe the vitreous bond wheels they sell for it as "straight" and "flaring." I assume that these mean Type 6 (straight-cup wheels) and Type 11 (flaring-cup wheels). I would further guess (and it's only that) that one could use a Type 12 (dish) wheel. A Type 1 (straight) wheel would fit, but the Tool Head really isn't designed to accomodate peripheral grinding, and I don't know if the spindle bearings are intended for it.

The maximum wheel diameter is 6 inches, as specified in the Model 375 Universal Cutter Service Manual (p. 8).

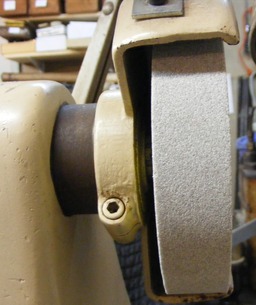

The maximum wheel width is 1 1/2 inches, as specified in the Famco manual (p. 8). It is good to know the official specification here, because 1 1/2 inches comes right up to the edge of the wheel guard. (A 1 1/4 inch thick wheel is a much more comfortable fit, but those are harder to find.)

The 375-4 has a spindle which terminates in a taper and a threaded portion. Famco p/n 1264-1, "Wheel Adapter," fits onto this taper and is secured by a nut on the threaded end of the spindle. Wheels are, in turn, mounted on this adapter. (If you have multiple adapters, you can just fit one to each wheel and, presumably, unmount and remount adaptor/wheel sets without re-truing the wheels.)

The 1264-1 Wheel Adapter has a 7/8 inch straight shank 1/2 inch long for mounting the wheel. Together with a screw-on flange, it accomodates wheels of 7/8 inch hole and 3/8 inch base thickness ( not 1/2 inch). These two dimensions present a considerable problem when shopping for wheels.

No 7/8 hole wheels seem currently to be manufactured. In itself this is not an insurmountable problem, as it is possible to use adapter rings to convert wheels with the more common hole diameter of 1 1/4 inches to 7/8 inch.

The real problem lies in the base thickness. 3/8 base thickness wheels of over 7/8 hole diameter are very hard to find. I've even had one grinding wheel distributor tell me that such wheels did not exist and that I'd have to have "superabrasive" CBN wheels custom-made for over $200 each. This is not true - but still suitable wheels are hard to find. The sections below are just my notes as I search for them. You should not rely on this - do your own research! I'm probably wrong, and I've certainly copied down some of those many-digit part numbers incorrectly.

Here is an example of a wheel which seems to be correct for this machine (assuming that it is motored and belted for a safe speed for this wheel). It is a Norton p/n H5571360: Type 6 (straight cup), 6" dia., 1 1/4" thick, 7/8" hole, 3/8" back thickness.

Note that while the guard accomodates 1 1/2 inch wheels, this 1 1/4 inch wheel fits much more comfortably.

The 7/8 inch hole in the wheel fits snugly on the Gorton p/n 1264-1 Wheel Adapter (the apparent eccentricity in the photo below is because the paper label/blotter is offset; the wheel itself fits snugly). Note also that a little bit of the cylindrical portion of the Wheel Adapter projects beyond the wheel itself. This gives sufficient room for the Wheel Adapter Nut, as shown below right.

Grinding wheels have been major industrial products for over 120 years. Grinding wheel nomenclature and the conventional designs of regular toolroom wheels have been standardized since the early 20th century. Now we're in the 21st century and one ought to be able to find any mass-produced industrial product online easily. But it is not so. Finding wheels appropriate for the Gorton 375 - which do exist - is unreasonably difficult. It involves having to track down and cross-reference literature both from manufacturers who often do not adequately describe their products and distributors who never do, all the while ignoring those distributors who assure you smugly that no such thing exists.

As of their current (2012) US catalog materials, Norton (now a brand of Saint-Gobain) lists no 6-inch Type 6 (straight cup) wheels with 3/8 inch backs.

Neither do they list any Type 6 wheels with 7/8 inch holes.

( Formerly they did manufacture such wheels.)

They do list five 5-inch Type 6 wheels with 3/8 inch backs and 1 1/4 inch holes. All are Type 6. 5 dia. x 1 1/2 thick x 1 1/4 hole, Rim 3/8, Back 3/8, and all are coded "ME19243":

(See p. 218 of the "Toolroom Wheels - Vitrified Wheels - Types 2/5/6/7" section of the Norton Industrial catalog, edition 7623.)

Local copy of 11/12/20/35 Toolroom Wheel catalog (downloaded 2012-04): private/NortonCatalog-ToolroomWheels-Type02-05-06-07.pdfprivate/NortonCatalog-ToolroomWheels-Type02-05-06-07.pdf

MSC does carry five of these, but it's a trick to find them in their system. Here are the MSC part numbers corresponding to the Norton part numbers:

As of April 2012 the three 32A wheels were going for $53.47/ea, quantity one, while the 38A wheel was going for $42.50.

The trouble with finding these is that you cannot find them in the MSC catalog (the "Big Book" for which they are justly famed). That doesn't list Norton part numbers, and gives an insufficient number of parameters to fully describe the wheels it lists. You have to find it by knowing, first, that Norton makes wheels of this description and then burrowing down through the MSC website product browser to get to a listing which shows these four wheels, with Norton part numbers. But that listing, in turn, is not sufficient on its own, because it neither fully describes the wheels (you must have the Norton catalog) nor uses adequate values for certain parameters (it doesn't list actual hardnesses, for instance (e.g., J or K) but rather just uses vague approximations ("coarse," "medium")). It does not specify the actual abrasive material at all (e.g., 32A vs 38A); you need to cross-reference to the MSC Big Book or the Norton catalog. Finally, the MSC online listing gives values for the face width which differ in two instances from those in the Norton literature (fortunately, that's not a critical dimension here).

Besides MSC, one's options are limited. McMaster carries some Type 6 wheels, but won't tell you the actual manufacturer's part number and doesn't fully specify any of them. Four of these Norton wheels are listed both by Grainger and Zoro Tools, but only in package (5) quantities. Other online source sell them only in packages of 10 (and at that they still come in at over $60/each). This is impractical for my small shop.

Note: For these other sources, searching on the code "ME19243" turns out to be more useful than searching on the actual part number.

Norton does list a few Type 11 (flared cup) wheels with 3/8 inch backs, but most of these have a 3/4 inch hole (too small). Only one single Norton Type 11 wheel has a 3/8 inch back and a hole size of at least 7/8 inch:

This wheel is difficult to find. Neither McMaster-Carr nor MSC carry it. Online, I could find it listed only by Production Tool Supply (Michigan/Ohio), X&D and Shamrock Supply. See below for one that I got from Production Tool . (Note that Production Tool has no idea what the Norton part number for this wheel is, but one cannot blame them, since the Norton (Saint-Gobain) company doesn't care to put its own part number on this wheel. It is identified only by the code "ME24327" on the wheel; you have to notice the code appended parenthetically to the product description in the Norton catalog.)

No Type 11 wheel listed by Norton of 4 inches or greater diameter has a back of 3/8 inch (they're all 1/2 inch).

Local copy of 11/12/20/35 Toolroom Wheel catalog (downloaded 2012-04): private/NortonCatalog-ToolroomWheels-Type11-12-20-35.pdf

The Norton literature does not list the back thickness of their Type 12 wheels. You'd think they'd know.

Carborundum (also a brand of Saint-Gobain) presents many more options, and documents them better.

Local copy of Carborundum Industrial Catalog (2012): private/Carbo-Industrial-Catalog-CA1000-2009-2010.pdf

Local copy of Carborundum Toolroom Wheels Catalog CA1000 (2012): private/carborundum-CatalogCA1000-ToolroomWhls.pdf

The Carborundum catalog CA100 "Toolroom Wheels," p. 82 lists several Type 6 wheels with 3/8 backs. Curiously, their 4" wheel is too deep overall (2"). But they list two 5" wheels (stock) and two 6" wheels (non-stock):

Type 6. 5 x 1 1/2 x 1 1/4 Rim 3/8 Back 3/8:

Type 6. 6 x 1 1/2 x 1 1/4 Rim 3/8 Back 3/8:

The same catalog, on p. 83, lists four Type 11 (3 1/2 / 2) x 1 1/2 x 1 1/4 wheels with 3/8 backs:

These are all listed as non-stock.

This same catalog lists nine Type 12 wheels with 5/16 or 3/8 inch backs and holes of over 7/8 inch, in all three of their abrasive types (AA ("good"), 32AR ("better"), "Medalist" ("best")).

Type 12. 6 dia. x 1/2 thick overall x 1 1/4 hole, 5/16 base:

Type 12. 6 dia. x 3/4 thick overall x 1 1/4 hole, 3/8 base:

Overall, the only problem with the Carborundum offerings for these dimensions is that they do not offer anything finer than 60 grit.

However, I have not been able to find any distributor online which both lists these Carborundum wheels and actually stocks them.

private/camel-grinding-wheel-standard-catalog-New-Vitrified-products.pdf

The current (as of 2012) Camel Grinding Wheels catalog lists several Type 6 and Type 11 wheels with 3/8 backs in reasonable sizes. Some of these are even listed as 80 grit (none of the Norton or Carborundum wheels are that fine, although Gorton was supplying 80 grit wheels decades ago). Finding a US distributor for Camel wheels is difficult, though. There are also issues with identifying wheels and with base thickness.

The first problem is that while the Camel literature is very good (see especially their "Standard Vitrified Abrasives Catalogue," available via their website), it identifies wheels in terms of an EAN Code. (Checking Wikipedia on this, EAN used to mean European Article Number, but is now the International Article Number. It is a superset of the more common Universal Product Code (UPC). What they actually specify is a 6-digit number, which must be half of an 12+1 digit EAN.)

But when one actually manages to purchase a Camel wheel, this number appears nowhere on it (or in the supplier's literature). Instead, there is a UPC (which seems unrelated to the EAN given in the literature, despite the note above) and a product "No." which is unrelated to all of the above.

So for example for Type 6 White Aluminum Oxide ("WA") toolroom wheels, they list no less than 13 wheels with a 3/8 inch recess. (Refer to their literature for the entire list.)

Moreover, they give a very nice table of "Standard dimension" for their Type 6 wheels. This table indicates that all of their 4-inch and 5-inch wheels have 3/8 inch backs.

With this table in mind, I went looking online. I couldn't find a regular Camel distributor, but I did manage to find a single wheel from I got this new, from stock, from Production Tool Supply (of Michigan and Ohio, online via http://pts-tools.com). It was listed as 5 x 1 1/2 x 1 1/4, "T6 WA60-J-V WHIT". This didn't correspond to anything at all in the Camel literature (which lists only hardness K wheels, not J). But the dimensions appeared to be ok, so I bought it.

What arrived (see photo below in Examples) was in fact a Camel Type 6 wheel 5 x 1 1/2 x 1 1/4. "WA60-J-V T6." It has two identifying codes on it: "UPC# 34933" and "No. A69036." Neither of these seems to have much to do with any of the EAN codes in the Camel literature.

This would merely have made purchasing Camel wheels an exciting lottery and new form of entertainment were it not for one further difficulty: the back thickness is somewhere between 3/8 and 1/2.

For reference, a Norton ME24327 Type 11 wheel, which is definitely a 3/8 inch back wheel, actually measures 0.423 in back thickness with the attached paper blotters/labels.

The Camel "No. A69036" wheel, with paper blotters/labels, measures 0.476. That's about 0.05 too thick, which is not a lot, but is enough that the Wheel Adapter blotter won't seat quite as far in as it should.

So for the moment, Camel wheels present tantalizing possibilities not available with Norton and Carborundum wheels (80 grit), but equally interesting mysteries.

Local copy of Famco catalog: private/famco-gorton-lars-current-catalog-2011-06-29--gorton_lars.pdf

The current (as of 2012) Famco catalog lists six vitreous bond wheels available from them for the Model 375-4. All are 6 inch diameter wheels with a 7/8 inch hole.

There is no indication as to which manufacturer's nomenclature is used for the Grade. Famco does refer to their "32-60" and "32-80" "grit" wheels as "Alundum." (I put "grit" in quotation marks because the "32" part is probably not a grit at all, but an abrasive material designation.) Alundum is (still) a Norton trademark for aluminum oxide products, but Norton makes many grades of aluminum oxide wheels, and tends no longer to use the term "alundum" for their toolroom wheels. Norton doesn't make an abrasive type 32 wheel, but does make an aluminum oxide abrasive type 32A. Famco does say that these wheels are "M5VBE", which is Norton nomenclature. The 'M' would indicate that they are a bit harder than the wheels commonly sold today for toolroom grinding (types J and K, often). The '5' refers to the grain structure, and is more dense than open. (The Norton p/n H5571360, no longer in production, was a 32A60-M5VBE wheel.)

The "RAA" for the other two wheels offered is Radiac (brand) nomenclature. Google knows nothing of an "RAA60L7V", which is remarkable, given how much Google does know.

| Catalog No. | Type | Grade | Non-Famco Notes |

| K6590 | Straight | Alundum 32-60 M5VBE | LARS K-6590 was Type 6: 6 x 1 1/4 x 7/8, 3/8 Back, 3/4 Rim |

| K6591 | Straight | Alundum 32-80 M5VBE | |

| K6592 | Flaring | Alundum 32-60 M5VBE | |

| K6593 | Flaring | Alundum 32-80 M5VBE | |

| K-6139 | Straight | RAA60L7V | |

| K6140 | Flaring | RAA60L7V |

They give no other dimensions. These part numbers correspond at to Lars part numbers, and in part to Gorton part numbers. I would assume that "Straight" means Type 6 and "Flaring" means Type 11, but that is just my assumption. One interesting thing that may be seen from this information is that the manufacturers intend the machine for use with 60 and 80 grit wheels. (But this can be seen from an examination of the wheel offerings in earlier Gorton catalogs, as well.)

Famco did not (in early 2012) reply to an e-mail inquiry for pricing on these wheels.

They also list six diamond wheels. All of the ones for the Model 375-4 are 7/8 inch hole:

With these diamond wheels, I don't know what "diamond grit on wheel periphery" means, since one doesn't grind using the periphery of a Type 11 wheel. Neither am I sure whether "Straight" and "Flaring" correspond to Types 6 and 11.

After a period of time looking for wheels to fit this machine, and being told by dealers (who ought to know; you'd think) that they don't exist, one begins to doubt oneself. Here are a few photographs of actual wheels, some from the past to prove that ideal wheels to fit this machine once did really exist, and some from the present to prove that wheels still exist which will work.

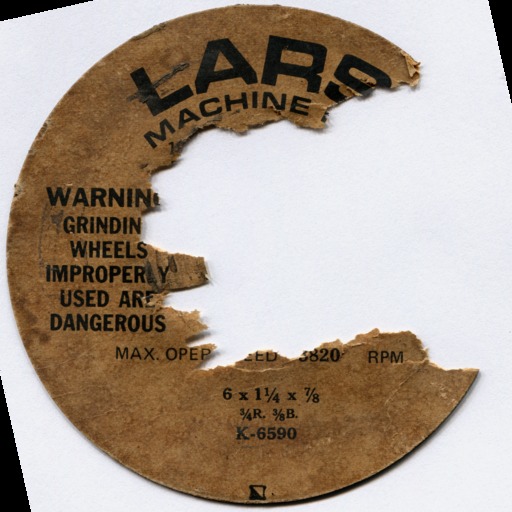

Here is an image of the label of a grinding wheel which came with my machine. (I apologize for their tattered state. This wheel, and the next one I'll show, were damaged as-received. I always destroy damaged grinding wheels lest I do something stupid (such as use them). It only occurred to me after I'd smashed them that it might be a good idea to save the labels.) I presume that both wheels were used with the machine. One was mounted on it as received, but I can't recall which.

This first label from a genuine LARS (successor to Gorton, predecessor to Famco) wheel, LARS part number K-6590. (A wheel of this part number is still listed by Famco, as a wheel of abrasive type 32 at 60 grit.) This is a Type 6 (straight cup) wheel, 6 inches in diameter and 1 1/4 inches thick (at the rim). It has a hole size of 7/8 inches. The rim is 3/4 inch wide, and the back is 3/8 inch thick. It will, therefore, fit the Gorton p/n 1264-1 Wheel Adapter perfectly. Note that the maximum operating speed is 3280 RPM, which is slower than the maximum spindle speed of the machine.

The next wheel (label) is a Norton, p/n D38353. It is a type 11 (flared cup) wheel, 6 inches maximum diameter and 5 inches diameter at the base of the flare. It is 1 3/8 inches thick (base to rim). It has a hole size of 7/8 inches. The rim is 1/4 inch wide, and the back is 3/8 inch thick. The 32A60-M5VBE describes the abrasive type (32A), grit (60), hardness (M) and bond type in Norton coding. This is also a 3820 maximum RPM wheel (the notation scrawled on it is mine, from a portion of the label which remained attached to the wheel). To the best of my knowledge this wheel is no longer in production.

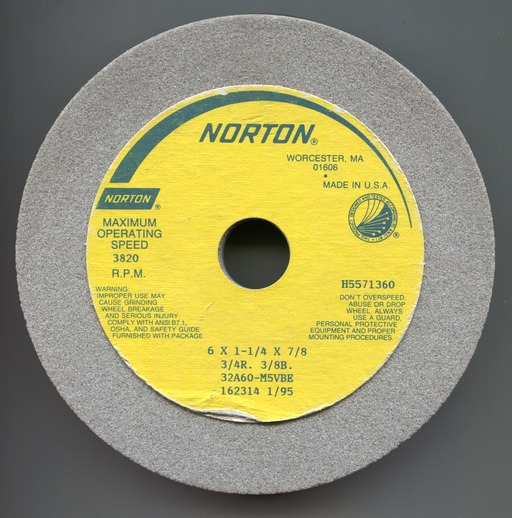

Here is a wheel I acquired more recently, although it is of older manufacture. It's a Norton Type 6 (straight cup): 6 inches diameter, 1 1/4 inches thick, 7/8 inch hole, 3/4 inch Rim, 3/8 inch Back. Norton p/n H5571360. 3820 RPM. Also 32A60-M5VBE. It's dated (by Norton) to January 1995, which is at least proof that 6 inch Type 6 wheels with 7/8 hole diameter and 3/8 back thickness were made until at least relatively recently. However, to the best of my knowledge, this wheel is no longer in production.

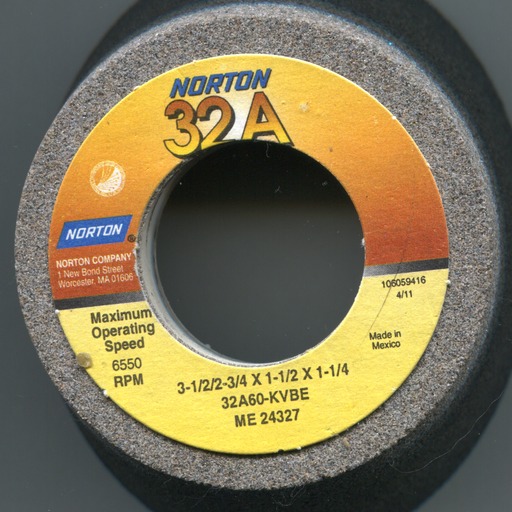

Here is an example of Norton p/n 66243529358 (that part number does not appear anywhere on the wheel, but the code "ME24327" does; the Norton Toolroom Wheel catalog links this code and the part number). Its dimensions are: (3 1/2 - 2 3/4) dia. x 1 1/2 thick x 1 1/4 hole, Rim 1/4, Back 3/8. 32A60-KVBE. Manufacture date 2011-04. I got this new, from stock, from Production Tool Supply (of Michigan and Ohio, online via http://pts-tools.com) in 2012-04. With an adapter to convert the 1 1/4 inch bore down to 7/8, this works just fine on my Gorton 375-4 with the standard p/n 1264-1 Wheel Adapter. The Norton product literature indicates a maximum speed of 7,640 for this wheel, but the wheel itself says 6550. Either speed (I would trust only the lower number on the wheel itself) is well in excess of the Gorton 375-4 spindle allowable maximum.

Note, however, that nowhere on the wheel (or on the supplier's web page for the wheel) does it give the thickness of the back. You just have to know that from reading the Norton catalog.

For the Norton specifications of this wheel, see the "Toolroom Wheels - Vitrified Wheels - Types 11, 12, 20, and 35" section of the Norton catalog, on p. 206 of the version online in (at least) April 2012.

Local copy: private/NortonCatalog-ToolroomWheels-Type11-12-20-35.pdf

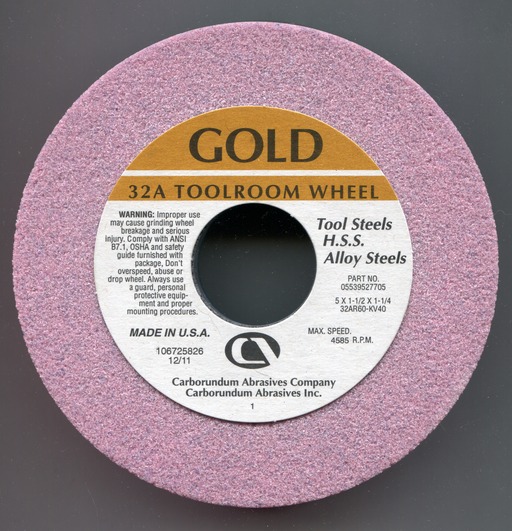

Here is an example of Carborundum p/n 05539527705. Type 6 (straight cup), 5 inch diameter. 1 1/2 inches thick, 1 1/4 inch hole. It has a 3/8 inch back, although this is not stated on the wheel anywhere (I guess Carborundum figured that saving a microgram of ink was worth the potential customer confusion that insufficient labelling causes.) Carborundum's grading for this wheel is: 32AR60-KV40 (abrasive type 32A (useful for HSS), 60 grit, hardness K).

With a 1 1/4 to 7/8 adapter, this should run on my Gorton 375-4.

I purchased this wheel new via the Internet from Production Tool Supply (of Michigan and Ohio). They had to backorder it, so it took a couple of weeks to arrive, but I've never seen a wheel packaged so well (encased in a cube of expansion foam). It was $32.90.

As discussed in the section above on Camel wheel availability, this wheel is a puzzle. Its identifying numbers do not correspond to the EAN codes in the Camel literature. Moreover, although the Camel literature gives the back thickness for all of their Type 6 4-inch and 5-inch wheels as 3/8 inch, the measured thickness of this wheel (with blotters/labels) in 0.476 (less than 0.5, but for reference a Norton ME24327 Type 11 wheel, which is definitely a 3/8 inch back wheel, actually measures 0.423 in back thickness with the attached paper blotters/labels.)

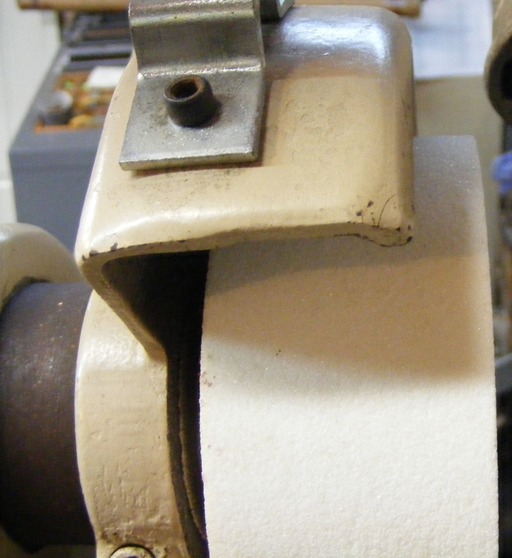

As can be seen in the photo below left, this wheel is definitely less than 1/2 inch thick (you can see the 1/2 inch cylindrical portion of the Wheel Adapter).

But the bearing surface of the hole in the wheel is in fact recessed, so that the Wheel Adapter Nut does not quite turn down enough, as seen below left. (Below right is a known 3/8 inch back wheel for reference.)

Here is a grinding wheel with a 1/2 inch back (a Type 11 wheel that I happened to have for another purpose) placed on the machine. At first, it might be thought that it fits, as the entire wheel fits on the 1/2 inch cylindrical portion of the Wheel Adapter.

But as seen below left, this is not sufficient; the Wheel Adapter Nut cannot be turned down sufficiently. As before, a 3/8 inch wheel is shown below right. The Wheel Adapter Nut in the case of the 3/8 inch wheel is fully engaged.

A 2-inch overall thickness (height) wheel (a Type 6 in this instance) placed on the machine is obviously wrong.

All portions of this document not noted otherwise are Copyright © 2012 by David M. MacMillan and Rollande Krandall.

Circuitous Root is a Registered Trademark of David M. MacMillan and Rollande Krandall.

This work is licensed under the Creative Commons "Attribution - ShareAlike" license. See http://creativecommons.org/licenses/by-sa/3.0/ for its terms.

Presented originally by Circuitous Root®

Select Resolution: 0 [other resolutions temporarily disabled due to lack of disk space]