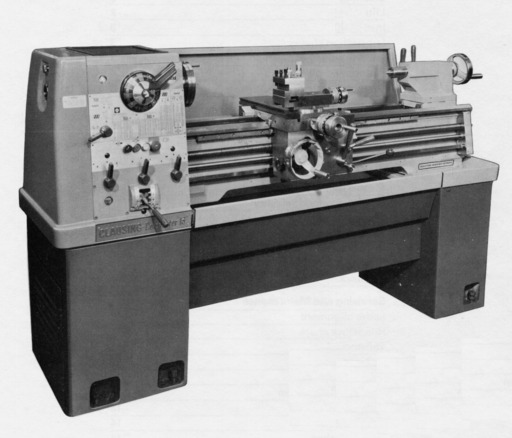

This section just has some notes relevant to my own lathe, the model sold in the US by Clausing as the Clausing-Colchester 13" but which is really the Colchester Master 2500 from England. (I have the short-bed version, 25" between centers.)

For more extensive information on Colchester lathes, see Tony Griffiths' www.lathes.co.uk website. For an online community devoted to Colchester lathes, see the Yahoo! "ColchesterLathe-User" group. The "Files" section of the group contains some manuals for other models.

Clausing-Colchester 13" Manual

The lathe came with a pretty decent manual. The icons at left and below link to local scan of it, done in three files: the manual itself, the illustrated parts list, and the illustrated parts list for accessories. (See the boxed "legal notices / fine print" section at the bottom of this page for a discussion of why I believe that this manual is in the public domain in the US). These files are large (178, 183, and 151 Megabytes). The final icon links to a PDF of just the lubrication chart, extracted from the manual (because I'm a bit obsessive about lubricating machinery).

FDK 3 Co. Service Manual

Shortly after I purchased my lathe, I also purchased a document with a dual title: "Secrets of Repairing Clausing-Colchester Lathes" / "13[inch] Colchester Service Manual" from Frank Kleinworth of FDK 3 Co., http://fdk3co.com. It is a combination of photocopies from the parts list pages of the manual together with rather detailed instructions covering a number of major service tasks (removing the main spindle, removing the clutch, disassembling the gearbox, etc.) I presume that these were written by Mr. Kleinworth; they have the air of a hands-on writer rather than a factory manual. My copy also included the "Dual Dials - Fitting Instructions" document (which originated separately; see below).

I think (but am not certain; it's been a long time) that this is the same document available from FDK3 Co. as the "Master Service Manual." They also offer reprints of the parts manuals for various models of Clausing-Colchester lathes.

Dual Dials - Fitting Instructions

This lathe could be fitted with dual-reading (inch/metric) dials on the topslide and the cross slide. The cross-slide dial is significantly more complex. These dials were manufactured by Gamet Products Limited ("GMT" on the dials), who are still in business as Gamet Bearings (now a division of The 600 Group, who also own the Colchester lathe brand). There was a four-page set of "Dual Dials - Fitting Instructions" published for them by Colchester.

I obtained a photocopy of this from Frank Kleinworth of FDK 3 Co., http://fdk3co.com. There are, however, several issues to be aware of with regard to this document. I should emphasize that none of these issues are the fault of FDK 3 Co.; they're simply doing the best they can with what is available.

First, the photocopy available via FDK 3 Co. is a multigenerational copy that is barely legible. I'm sure that it is the best that is available, however.

More significantly, this document describes the fitting of Top Slide dials which differ from those installed on my machine. Mine is a fairly late serial number machine, and I presume that it has a later style of Top Slide dial. The dials described use a "Retainer Plug" which is unscrewed "using peg-spanner supplied with the lathe". The Top Slide dial on my machine has, instead, p/n "87520-0 washer (931-0294)," the removal of which requires no tool (see p. 18.1 CL of the Spare Parts Section of the manual, above).

Most significantly, the document is intended for "fitting" the dials in the sense of installing them on the machine. It basically contains instructions for removing existing dials and putting on new ones. It does not contain any information at all about the internal details of the dials, or how to actually service the dials. (It says that they "should not normally require further attention," which is manifestly untrue in the case of my machine.) The only sources of information that I know of about the internals of the dual dials are the patents for them (see below; but even these require care in interpretation).

Gamet Products Limited held patents for (at least) three essentially different kinds of dual-reading handwheels. They were/are located in Colchester, and at present are owned by The 600 Group (who also own the Colchester lathe company). All three patents employ a pair of gears, one of 125 teeth (for metric) and of 127 teeth (for inch), to give "continuous" readings where metric and inch graduations continue sensibly through multiple rotations. They differ, however, in the way in which these computational gears are engaged.

In the first (GB 1,193,831, Sindall) the inch and metric gears are connected with a fixed idler (and compute). However, for inch readings they are disengaged (using a friction clutch) and do not rotate. For metric readings, they are engaged via a friction clutch and rotate and calculate metric readings.

In the second (GB 1,265,994, Waplington) the idler pinion between the two gears floats freely for inch readings (metric not being computed) and is engaged for computing metric readings.

In the third (GB 1,463,732, Hill) the pinion is fixed and the two computing gears are continually engaged (and continually computing both inch and metric readings). An external sleeve is rotated 180 degrees by the operator to expose either inch or metric readings, as desired.

Dual Dials - GB Patent 1,193,831

GB patent specification 1,192,831, "Improvements in Dial Assemblies." Application No. 3182/68, filed 1968-01-22. Complete specification filed 1969-01-02 and published 1970-05-20. Invented by Charles Peter Sindall and issued to The Colchester Lathe Company Limited. It is interesting that this patent's filing (but not publication) predates that of the Waplington/Gamet patent GB 1,265,994.

This patent describes a mechanism which involves a fixed idler gear (unlike GB 1,265,994, but more like GB 1,463,732, both below). However its essence is a longitudinally sliding sleeve which in one position engages via friction with the handwheel itself and displays "native" inch graduations or in the other position engages via friction with a geared inch/metric calculating mechanism and displays metric graduations. This differs entirely from GB 1,463,732 below, where the inch/metric conversion mechanism is in continual engagement.

This mechanism is different from that fitted to the Top-Slide Dial of my own lathe, a relatively late serial number example of the model sold in the US by Clausing as the Clausing-Colchester 13" .

The copy of the specification here is one that I downloaded from the European Patent Office ( http://worldwide.espacenet.com/advancedSearch?locale=en_EP). An eqivalent copy is also in the Yahoo! ColchesterLathe-User group Files section.

Dual Dials - GB Patent 1,265,994

GB patent specification 1,265,994, "Improvement in Dial Assemblies." Application No. 5192/69, filed 1969-01-30. Complete specification filed 1970-01-09 and published 1972-03-08. Invented by Gerald Andrew Pearson Waplington and issued to Gamet Products Limited (Hythe, Colchester, UK). This would seem to be the original version of US patent 3,696,776 (see below).

This patent describes a form of dual-reading dials which employs two "calculating" gears (125 tooth and 127 tooth) and a pinion gearing them together (this is common to all three Gamet patents here) but which differs from both GB 1,193,831 and GB 1,463,732 in that in one system of measurement both gears rotate together without relative motion (the idler itself does not rotate) and "native" (inch in this case) readings are made visible, while in the other system of measurement the idler is fixed to the frame and causes, therefore, a relative motion of the two "calculating" gears (in this case computed (metric in this case) readings are made visible.

This mechanism is different from that fitted to the Top-Slide Dial of my own lathe, a relatively late serial number example of the model sold in the US by Clausing as the Clausing-Colchester 13" .

The copy of the specification here is one that I downloaded from the European Patent Office ( http://worldwide.espacenet.com/advancedSearch?locale=en_EP). It is not (at present) in the Yahoo! ColchesterLathe-User group Files section.

Dual Dials - US Patent 3,696,776

US patent 3,696,776, "Dial Assemblies," issued 1972-10-10 to Gerald A. P. Waplington and assigned to Gamet Products Limited (Hythe, Colchester, England). Filed 1970-01-19 as application serial number 3,918. N.B., the Foreign Application Priority Data for "Great Britain ...... 5,192/69" on 1969-01-30 is for the GB patent issued as 1,265,994 (see above). The drawings in this patent are better than those in its English equivalent.

The copy of the specification here is one that I downloaded from the USPTO and assembled into a PDF (using a hacked version of the pat2pdf script) An equivalent copy is also in the Yahoo! ColchesterLathe-User group Files section.

Dual Dials - GB Patent 1,463,732

GB patent specification 1,463,732, "A Device for Indicating Translational Movement of a Member Selectively in One of Two Systems of Units." Application No. 48559/74, filed 1974-11-08. Complete specification filed 1975-10-03 and published 1977-02-09. Invented by Stanley Hill and filed by Gamet Products Limited (Hythe, Colchester, UK).

This patent describes a mechanism which involves a fixed idler gear (unlike GB 1,265,994 above, but more like GB 1,193,831 above). However, the essence of its display mechanism is a rotatable sleeve which may be rotated 180 degrees to show either the inch or the metric graduations of an inch/metric conversion mechanism which is in continual engagement. This differs entirely from GB 1,193,831 above, where the inch/metric conversion mechanism is selectively engaged or disengaged.

This patent describes very nearly the top slide dial fitted to my own lathe, a relatively late serial number example of the model sold in the US by Clausing as the Clausing-Colchester 13" .

The copy of the specification here is one that I downloaded from the European Patent Office ( http://worldwide.espacenet.com/advancedSearch?locale=en_EP). An eqivalent copy is also in the Yahoo! ColchesterLathe-User group Files section.

I believe that the manual for the Clausing-Colchester 13 inch lathe is in the public domain in the US. If this manual were an English publication, it would have been in the public domain in the US at time of publication in the early 1970s due to failure to comply with required notices. However, since the 1996 implementation of the Uruguay Round of the GATT talks in US copyright law non-US publications, even if formerly in the public domain, were placed in copyright in the US as if all requirements had been met. This means that the English edition of this manual is now in copyright in the US. However, this is not the English edition of this manual. It is a US publication, published by Clausing Machine Tools. It was published at the time of the manufacture of this lathe in the 1970s. (It was printed in England, but it was published in the US. Similarly, many books today are printed in China but still published in the US. Printing and publishing are separate activities.) It was also published without copyright notice, which would have been required at that time to secure US copyright. I believe, therefore, that the US (Clausing) edition of this manual passed into the public domain in the US upon initial publication due to failure to comply with legal requirements then in effect, and that it remains in the public domain in the US. I am reprinting it here in good faith given this belief. I assert no additional copyright on it; if it is indeed in the public domain in the US, as I believe, then this digital reprint remains in the public domain.

GB patent specifications published before 1989-08-01 are subject to Crown Copyright for a period of 50 years. However, the (UK) Copyright, Designs and Patents Act of 1988, Section 47(3) allowed the "appropriate person" to authorize the dissemination of documents of "general scientific, technical, commercial or economic interest" without copyright infringement. The (UK) Comptroller of Patents authorized this for UK patents in the Official Journal of Patents, 6 March 1991. The presentation of these GB patents here is done under those terms.

US patent specifications are in the public domain by law.

All portions of this document not noted otherwise are Copyright © 2012 by David M. MacMillan and Rollande Krandall.

Circuitous Root is a Registered Trademark of David M. MacMillan and Rollande Krandall.

This work is licensed under the Creative Commons "Attribution - ShareAlike" license. See http://creativecommons.org/licenses/by-sa/3.0/ for its terms.

Presented originally by Circuitous Root®

Select Resolution: 0 [other resolutions temporarily disabled due to lack of disk space]